Capabilities

From ideation to delivery, our production capabilities are the most versatile in the industry.

With nearly 75 years of experience and the latest fabricating tech, we are able to create almost any display from an incredible array of materials. If you can imagine it, we can build it to suit your display needs.

Laser Cutting and Engraving

Astro Display’s laser cutting and engraving services allow us to take your display to the next level. In addition to cutting parts, lasers allow us to strengthen your brand by adding your logo or other intricate, decorative details. These precision engraving techniques can be applied to a variety of materials and surfaces, including plastic, wood, glass, paper and metal.

Applications for lasers include:

- Displays and fixtures

- Acrylic blocks

- Signs and sign holders

- Display case covers

You can rely on Astro Displays to achieve all your cutting, etching and engraving needs quickly and within your budget.

Woodworking and Cabinetry

Astro Display Company offers full-service woodworking capabilities to meet your wood fixture, shelving, cabinet and countertop display needs. Our designers use a myriad of versatile wood materials to integrate a wide variety of sizes, contours, and styles to build the display that works perfectly for your retail space.

Plastic Thermoforming

Our plastic thermoforming operations include drape forming, vacuum forming, line bending, blow forming, and pressure forming. These thermoformed plastic parts are used in a number of other industries, including aerospace, automotive, and medical. We commonly use acrylic, polycarbonate, styrene, and ABS in both colored and tinted forms.

Plastic parts that require shapes having gradual bends, such as curved cabinet windows, boat windows and machine guards, can be produced in our drape forming operations. With our vacuum forming process, complex and elaborate plastic shapes such as product trays, speaker casings, and automotive components can be produced. Specializing in thermoforming many materials, we can shape plastic products with thickness ranging from 0.060″ to 3″.

Sewing

Often used with jewelry displays, Astro’s expertise with sewn fabrics will help you achieve that elegant, high-end look. Adding padded, sewn features to jewelry displays helps protect surfaces from scratching and makes small pieces easier to display and handle. We can work with your selected fabrics or you can allow us to select a fabric on your behalf.

Printing, Polishing and Decorating

We offer a wide range of finishing options, including flame, buff, solvent, machine and hand polishing. Our buff polishing, flame polishing and Bermaq machine polishing offers a lustrous finish on cast acrylics. We often use hydrogen/oxygen flame to polish the edges of acrylic and plastic components. Our flame polishing process is a quick and cost-effective method that can restore the leading edge of an acrylic panel to its original clarity. Hand polishing and buffing ensure smooth edges throughout each piece.

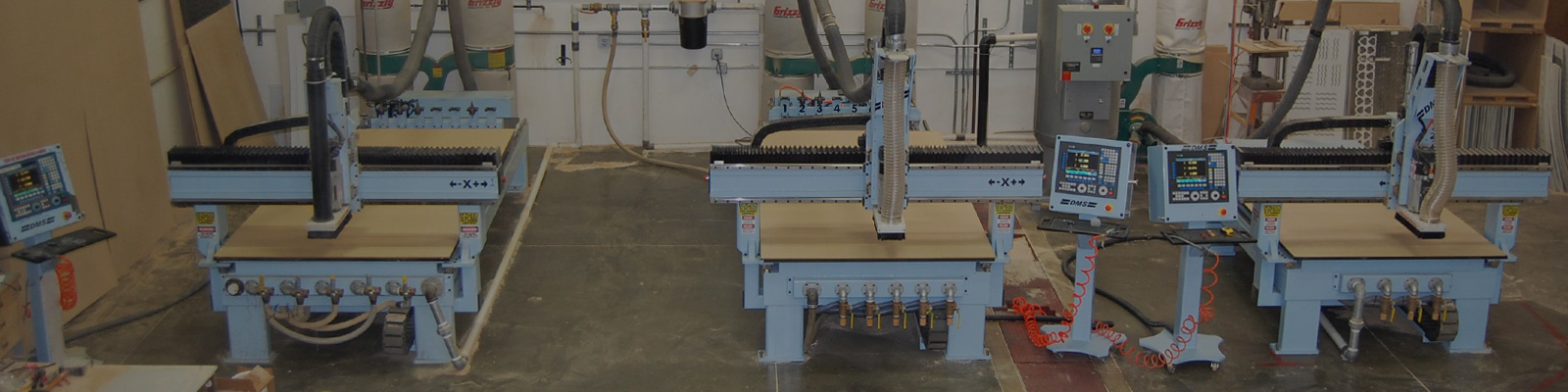

3-Axis CNC Routing

We perform CNC routing for prototype, tooling, and production parts with tight tolerances ranging in the 0.015”range. 3-axis CNC routers ensure high-speed automated routing in all types of wood and plastics. Our CNC routing facilities allow us to produce complex shapes and designs with good dimensional stability.

2D as well as 3D cutting can be quickly set up and programmed in our CNC routers. Our 4 x 8-foot and 6 x 10-foot moving tables provide a wide machining area for cutting both wood and plastic. A multi-position automatic tool changer option in each router ensures concurrent, multiple routing operations. Materials with thicknesses ranging from 0.060 inches to 2 inches can be cut on our CNC routers. Customer designs are accepted in many formats (see below). After cutting, we also finish routed parts through sanding and polishing.

Plastic Fabrication

We know plastic and acrylic fabrication! Our fabricating capabilities extend from cutting and CNC routing to thermoforming and we handle all types of complex acrylic and plastic fabrication jobs. Our 3-axis CNC router handles both 2D and 3D cutting operations.

Astro Display’s thermoforming capabilities include plastic draping, vacuuming, and plastic blow forming. Depending on the material thickness, plastic sheets can be bent up to 180 degrees.

We fabricate plastic parts from a wide range of materials, including acrylic, PVC, polycarbonate, and styrene. Additional fabrication processes such as plastic gluing and bonding can also be performed. Products can be finished through sanding and polishing.

Astro Display Company has nearly 75 years of experience in the plastic fabrication industry, and we handle prototyping and high-volume production in-house.

Materials used include:

- Acrylic

- PETG

- PVC

- Styrene

- Expanded PVC

- ABS

and more!